Grease lubrication system

Grease System Outline

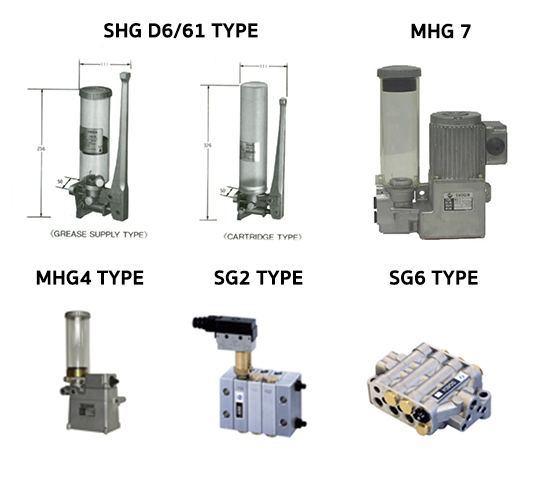

GREASE LUBRICATION SYSTEMS

The SHOWA grease system comprises of various sub-lubrication systems, offering different methods of distribution and discharge. The 3 main grease lubrication sub-systems, allows a broad range of lubrication requirements to be catered for.

PROGRESSIVE SYSTEM

Pressurized grease is forwarded to individual lubrication points in sequence by utilizing progressive type (volumetric) distribution blocks. As the pistons in the Dester G block (SG) move in sequence to distribute grease, the Dester G block will not be able to function if a single port is sealed. This characteristic of the system helps simplify monitoring and lubrication management. By confirming operation at the Dester G blocks, it is possible to identify lubrication problems from a centralized point. If a port(s) is not required, attachments (PSG) can be used to combine ports. Additional Dester G blocks can be attached to upper level (parent) blocks, broadening the lubrication system to meet varying requirements.

| No. | Code | Description |

|---|---|---|

| 1 | MHG | Pump |

| 2 | SG608A | Distribution Block |

| 3 | SG606B | Block With Indicator |

| 4 | SG612A | Distribution Block |

| 5 | PSG104 | Attachment |

★Section Pipe Fittings & Parts

| Pipe Size | Fittings Utilized |

|---|---|

| φ8 | PD801,PA8,PB8 |

| φ6 | PD6,PA6,PB6 |

●Section Pipe Fittings & Parts

| Pipe Size | Fittings Utilized |

|---|---|

| φ8 | PA6,PB6 |

| φ6 | PD604,PA4,PB4 |

SINGLE-LINE SYSTEM

Grease is forwarded to individual lubrication points simultaneously by triggering volumetric distribution equipment with intermittent pressure fluctuations and depressions. This action can be performed by a pump possessing a pressure displacement mechanism. Volumetric distribution blocks with differing discharge volumes can be utilized and incorporated into a single lubrication system. This flexibility with discharge volumes simplifies system layout and planning, enabling the single line system to be ideally suited for a wide variety of lubrication systems and situations. Monitoring and general lubrication management can be simplified and performed by installing pressure switches and distribution blocks with indicators at required locations.

| No. | Code | Description |

|---|---|---|

| 1 | GPMW | Pump |

| 2 | 01050613 | Connector |

| 3 | 01050610 | Connector |

| 4 | PGL250 | Pressure Gauge |

| 5 | JHD3S | T – Connector |

| 6 | 01040600 | T – Connector |

| 7 | GDB6K | Junction Block |

| 8 | DG50 | Piston Distributor |

| 9 | PA4 | Bushing |

| 10 | PB4 | Sleeve |

| No. | Code | Description |

|---|---|---|

| 11 | PD4 | Nipple |

| 12 | PH4 | Elbow |

| 13 | DGE20 | Flow Sensor |

| 14 | GDB4K | Junction Block |

| 15 | PG1 | Plug |

| 16 | DG3 | Piston Distributor |

| 17 | GDB7K | Junction Block |

| 18 | DG30 | Piston Distributor |

| 19 | PQ101 | Connector |

| 20 | GDB5K | Junction Block |

RESISTANCE SYSTEM

By applying different amounts of resistance at the resistance type distribution junctions or lubrication points, the grease from the pump can be divided and discharged proportionally. Unlike the progressive or single-line systems, resistance type systems are unable to measure specific volumes for discharge past the pump unit.Ideal for smaller scale lubrication requirements (Under 10 lubrication points with distribution piping not exceeding 5m in length). Lubrication systems can be installed and operated at minimal expense due to the simple nature of the components and system. Fixed and adjustable resistance applying distributors are available to simplify installation.

| No. | Code | Description |

|---|---|---|

| 1 | SHG | Pump |

| 2 | DB | Junction Block |

| 3 | CSS | Continuous Unit |

| 4 | PAN4 | Nut |

| 5 | PB4 | Sleeve |

| 6 | PD110 | Adapter |

| No. | Code | Description |

|---|---|---|

| 7 | PA6 | Bushing |

| 8 | PB6 | Sleeve |

| 9 | PD4 | Nipple |

| 10 | PA4 | Bushing |

| 11 | PH4 | Elbow |

| 12 | PG004 | Plug |